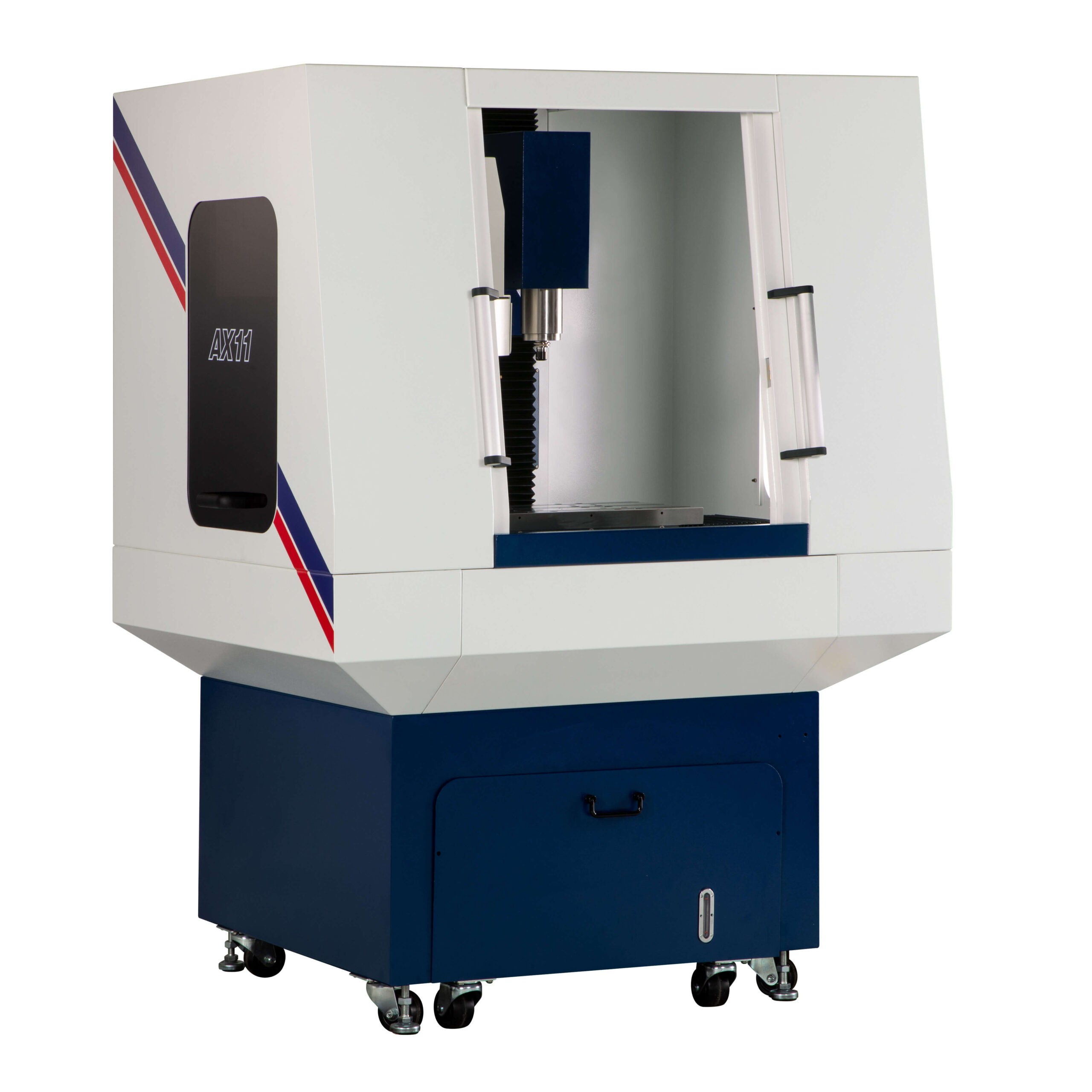

The AX11 series of small CNC integrated machines is primarily designed for metal processing, allowing for easy and high-precision metal processing in limited spaces. The machine is made of high-strength cast iron with a ground worktable surface, and features full ball screw and linear guide transmission, achieving accuracy of up to +/- 0.02mm.

Equipped with an internal 24000rpm high-speed ATC spindle and high-performance servo motors to achieve fast and precise processing while maintaining a high-quality user experience. Additionally, the machine is equipped with an automatic tool change system that provides a variety of metal processing tool options to meet different processing needs.

The AX11 small CNC integrated machine is ideal for manufacturers and makers who need to perform high-precision metal processing in limited spaces, especially for small batches and multiple varieties of production needs. The machine’s simple and user-friendly interface and easy-to-operate controller allow you to quickly get started, thereby increasing production efficiency and product quality more effectively. This series is your best choice for achieving high-precision metal processing goals.

- Cutting size: 350x300mm

- Cutting height: 350mm

- Processing materials: metal, wood, plastic, carbon fiber, etc.

- Processing types: high-speed engraving

- Suitable for precision parts carving and shaping

- Excellent minimum footprint

Controller:

- i-CNC : New UI system with a 21.5″ touch-screen monitor.